Dealing With Aging of Facilities

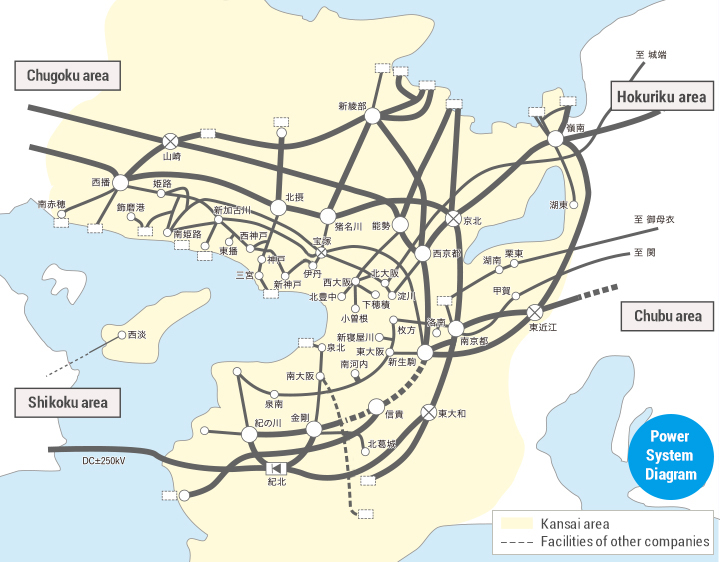

Power Distribution Facilities Owned by Kansai Transmission and Distribution

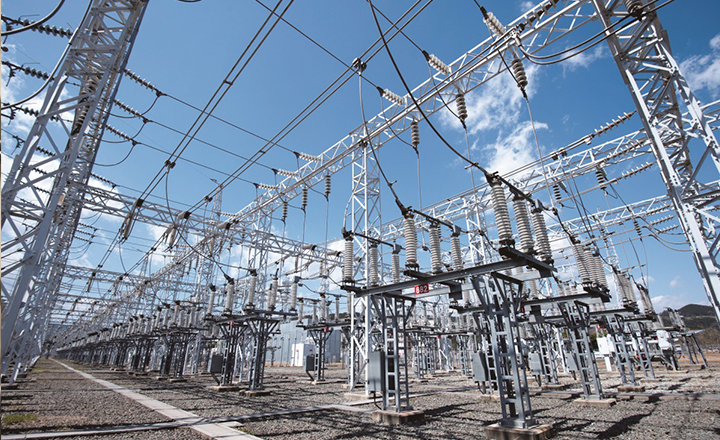

We own and maintain a huge number of power distribution facilities installed throughout the Kansai area, supporting the safe and stable supply of electricity every day.

Flick for details.

Number of steel towers

31,411

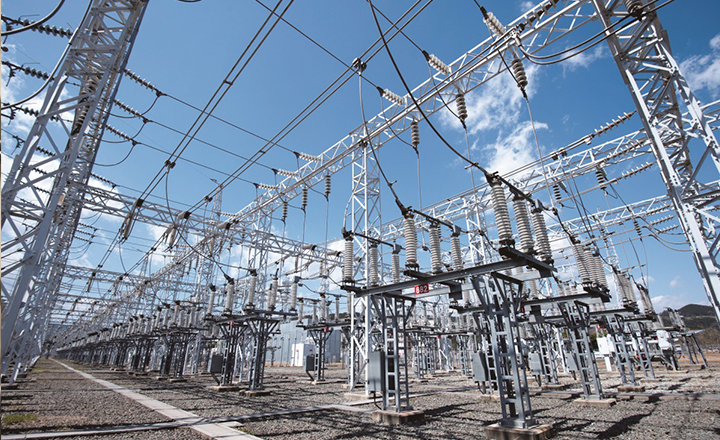

Number of transformers

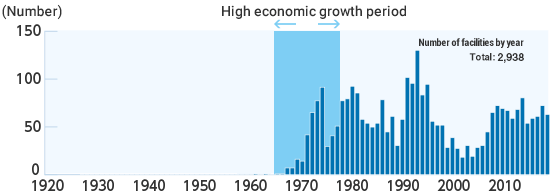

2,938

Number of concrete poles

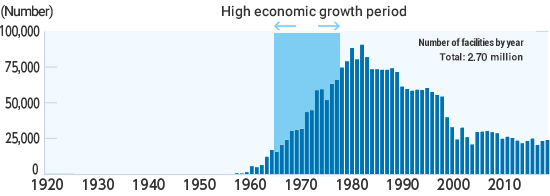

2,700,000

- * As of end of March 2020

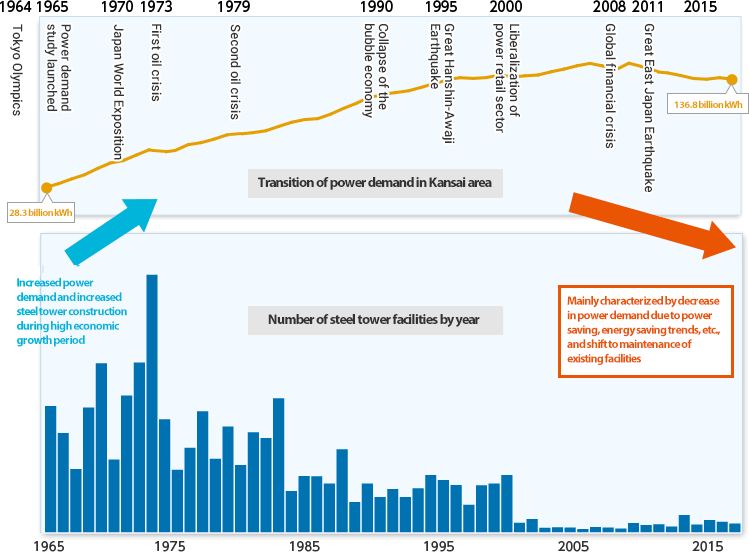

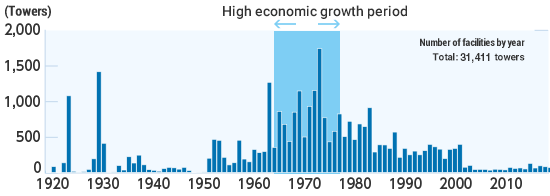

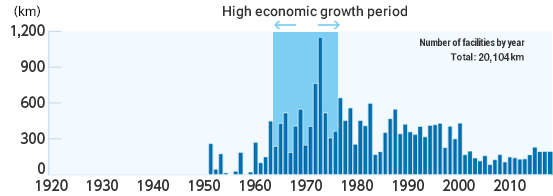

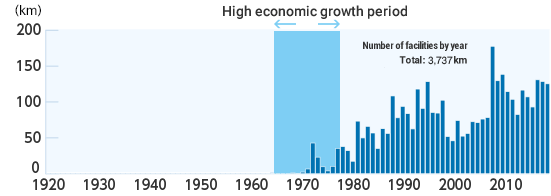

Relationship Between Power Demand and Power Distribution Facilities in the Kansai Area

Until now, we have built a large number of power distribution facilities in line with the strong growth in electricity demand during the period of high economic growth.

On the other hand, power demand has been leveling off and declining in recent years, due to the spread of power-saving equipment and devices. Construction opportunities for power distribution facilities therefore have decreased, shifting the focus to the maintenance of existing facilities.

Flick for details.

Impact of Aging Power Distribution Facilities

As power distribution facilities are subject to the effects of aging, the number of facilities that have deteriorated will increase, and the volume of materials required for maintenance will expand significantly. Amid such concerns, we are carrying out appropriate maintenance and are implementing suitable measures against the effects of aging, in order to continue to deliver safe, stable, and low-cost electricity to all our customers.

Examples of aging

Problems such as shown below are expected to increase in future.

Aging of steel tower

(Rusting of steel tower members)

Aging of transformer

(Oil leakage from transformer)

Aging of electric pole

(Concrete peeling)

(Rust on internal rebar)

Initiatives to Deal With Aging

To counter the effects of aging, we are implementing measures designed to minimize the increase in maintenance costs while maintaining a stable and safe supply.

Utilization of new technology and innovation, and increasing construction capabilities

Distribution of Power Distribution Facilities Aging

In many power distribution facilities, equipment replacement costs are showing an upward trend, due to an increase in the replacement volume of facilities installed during periods of high economic growth, as seen from the viewpoint of aging distribution. In order to maintain the level of service that our customers have a right to expect, and to minimize future outsourcing costs, we will formulate a capital investment plan that covers various aging related measures and ensures the proper timing of renewed construction work.

Steel towers

Flick for details.

Overhead wires

Flick for details.

Underground cables

Flick for details.

Transformers

Flick for details.

Concrete poles

Flick for details.

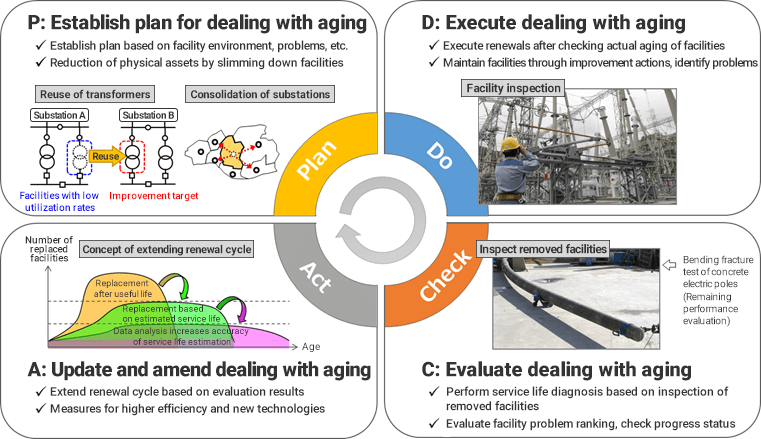

Renovation Plan to Counter Aging

Regarding measures against aging, each year a renovation scheme will be put into practice, consisting of the following action sequence: “P: Establish a plan reflecting current needs and the state of deterioration of equipment,” “D: Verify the deterioration state and execute the actions of the plan,” “C: Perform deterioration analysis to evaluate the appropriateness of the plan,” “A: Update and amend the plan as needed.”

Flick for details.

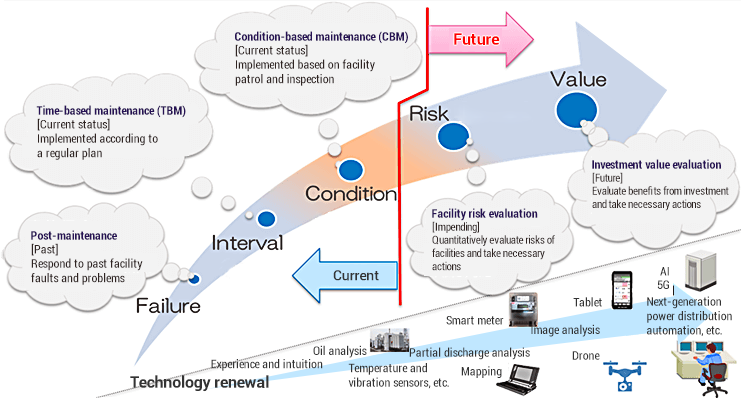

Future Policy With Regard to Measures Against Aging (Introduction of Asset Management)

In the context of countermeasures against aging, we will utilize a wide variety of data about facilities, based on sophisticated asset management using IoT, AI, etc. to understand the possibility of equipment failure. In addition, we will evaluate the impact level, quantitatively evaluate equipment risks, and aim to optimize the renewal timing.

Looking towards the future, we will make comprehensive capital investment decisions to maximize the investment effect.

Flick for details.

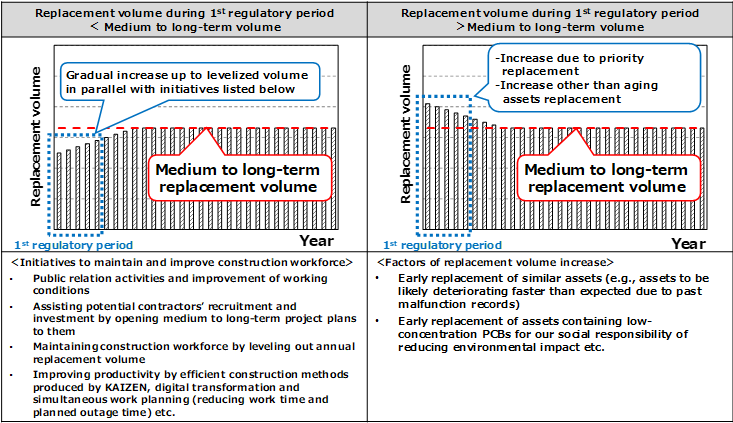

Asset Volume to be replaced during the first regulatory period (of Revenue Cap scheme)

- Replacement volume during the first regulatory period is basically set by the medium to long-term replacement needs of aging assets, which are expected to increase in future.

- Then, replacement volume is further adjusted in consideration of the construction workforce maintenance or improvement initiatives and detail reasons for replacement priority.

Flick for details.

For details on the volume of replacement, please refer to the detailed business plan, which is available in Japanese only.

Securing Human Resources to Bolster Construction Capabilities

In dealing with the expanding maintenance and renewal requirements of aging facilities, securing sustainable construction capabilities in the future is necessary. As a general power transmission and distribution company, we endeavor to gradually expand our scope for facility renewal as described above while striving to expand our construction capabilities.

To secure sufficient construction capabilities, we are looking at various ways to attract new employees, including by reducing the load on workers through mechanization, by improving the working environment through the adoption of construction plans that take into account holidays and two days off every week, and by using recruitment pamphlets in cooperation with the Kansai Branch of the Transmission Line Construction Engineering Society of Japan.

In our effort to prepare for the continued aging of distribution facilities constructed during the period of high economic growth, we will continue to implement measures such as improving the working environment to facilitate labor and increasing occupational awareness.

Conclusion

There is a concern that aging of a large number of facilities in the future will lead to increased maintenance and repair costs, but we are working on measures to deal with this problem in a systematic and efficient manner while minimizing the increase in costs.

Safe and Stable Supply Menu